DIY 3D-printing earmould production is a growing EU trend says Swiss software company behind Secret Ear Builder

Switzerland-based CAD software producer Cyfex has highlighted a growing trend for hearing aid dispensers to set up their own earmould production lines using 3D-printing.

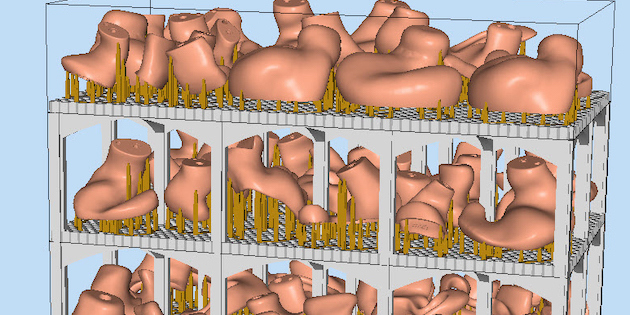

In July, Cyfex released version 5.3 of its build preparation programme for earpiece – Secret Ear Builder – which facilitates what the company has heralded as a strong recourse for dispensers who want maximum control over the accuracy of earpieces.

Are UK professionals lagging behind their EU counterparts in setting up earmould production?

Cyfex has identified a strong tendency among professionals to establish their own 3D-printing earmould set-ups, particularly in France and Germany, but also in Belgium, Spain, Italy, Austria, the Netherlands, and Poland. The tendency is not so strong in the UK, claims Cyfex. The company suggests this may be down to differences in training and division of tasks.

The development of 3D-printing methods has meant traditional large-scale earmould labs within the industry now have growing competition from smaller labs and set-ups in practices. “Both labs and dispensers are constantly working towards being able to provide better fitting earmoulds because this increases end customer satisfaction,” said a Cyfex spokesperson.

Secret Ear Builder 5.3 can be tested for free

Build preparation for earmoulds – i.e. putting together a (virtual) platform for subsequent 3D printing – is tricky and time consuming. Cyfex claims its latest software focuses on a lean workflow, and is a valuable time and resin saving tool for any earmould lab. The software can be tested for free.

Among other conveniences, Secret Ear Builder brings:

- optimized orientation with special consideration of the particularities of earpieces;

- optimized nesting to be able to fit more models on the platform;

- stacking;

- croppable baseplate for the last printjob in the day;

- barcode support;

- automated PDF and CSV report for quality assurance.

For more details on Secret Ear Builder, click here.

Source: